A team of Japanese scientists made history when the world's first wooden satellite, LignoSat, not only successfully entered orbit but also survived an incredible 116 days.

Despite communications problems, this initial success opened the door for LignoSat-2 and hopes for a future where wood replaces aluminum in the space industry.

Professor Takao Doi, a former astronaut and the main inspiration behind the project, has always dreamed of wooden structures in space, inspired by ancient temples in Kyoto that have existed for more than a millennium.

“If we can use wood in space, we can develop sustainable space forever,” he shared.

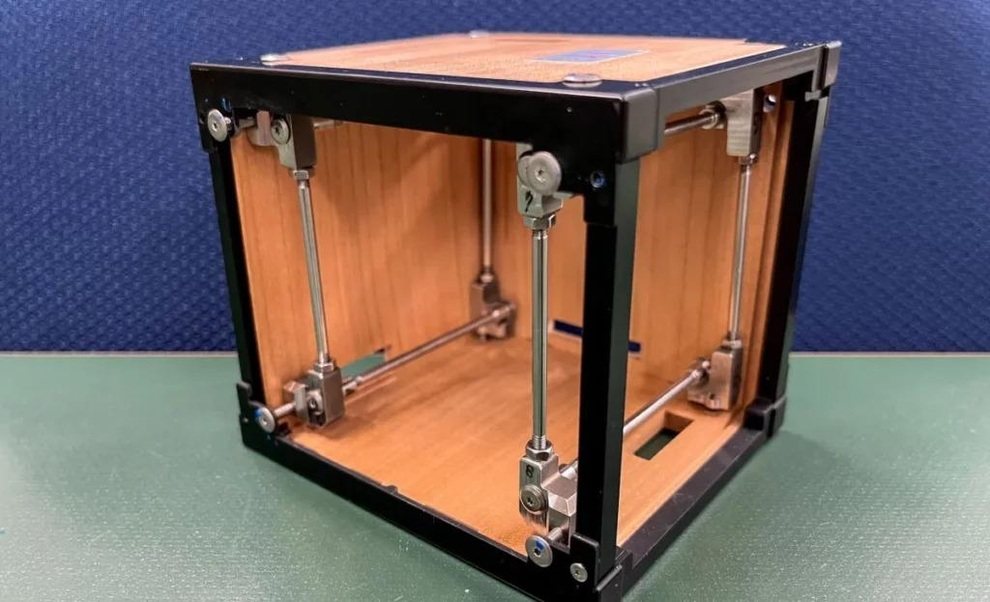

The idea of a “wooden space age” gained traction last year with the launch of LignoSat, the world’s first wooden satellite. Developed by Professor Doi, a team of scientists from Kyoto University and logging company Sumitomo Forestry, LignoSat is a compact CubeSat that is relatively cheap and easy to build.

The project's main goal is to reduce the spacecraft's environmental impact, as wood is a renewable material and creates less pollution when burned upon re-entry into Earth's atmosphere.

LignoSat was deployed by the Japan Aerospace Exploration Agency (JAXA) from the International Space Station (ISS) and operated in orbit for 116 days.

While it was a huge success in terms of physical survival, LignoSat encountered an unfortunate problem: Scientists in Kyoto were unable to communicate with it after its launch on December 9, 2024.

This left four of the five main research objectives, including measuring deformation, temperature, magnetic permeability and the effects of space radiation on wood, unfulfilled. “Unfortunately, we didn’t get any of the information we wanted to know,” admits Professor Doi.

Initial analysis points to two potential failures: One or all three switches that activate the system and the satellite's antenna may not be turned on, or the computer program may not have initialized properly.

Despite the communications system failure, LignoSat still achieved two important achievements.

First, it demonstrated that a wooden satellite could survive in orbit without breaking apart, which was unprecedented. Second, it streamlined the safety review process for wooden spacecraft with NASA – paving the way for subsequent wooden satellites to be more easily licensed.

Building on the lessons learned, Professor Doi and his colleagues are developing LignoSat-2, scheduled for launch in 2028. LignoSat-2 will be twice the size of the first LignoSat, with two communications systems (one inside the structure and one mounted on the surface) to ensure that communication failures do not repeat themselves.

Installing the antenna inside the satellite body would also reduce drag as it orbits the Earth.

Environmentally friendly

Professor Doi shares a bigger ambition: “Let’s create a space wood industry.” He envisions a future where wood replaces aluminum as the primary material for satellites.

Wood is cheaper, easier to use and lighter than conventional spacecraft materials, making space development more accessible to countries with fewer resources.

When conventional satellites re-enter the atmosphere, they burn up and create tiny particles of aluminum oxide, which can destroy the ozone layer, disrupt atmospheric processes and even alter the Earth's magnetic field.

In contrast, when wood burns, it only produces carbon dioxide, biodegradable ash, and water vapor, which are much more environmentally friendly products.

Although further research is needed, wood decomposition products are easier to assess because they are the main drivers of atmospheric processes.

Currently, with a few hundred tracked objects returning to Earth each year, the degradation of metal spacecraft is not a major environmental issue. However, as the space industry rapidly expands, the search for more environmentally friendly materials is becoming more urgent.

Replacing even a small part of the satellite's components with wood could significantly reduce pollution, said Jari Mäkinen, co-founder of Arctic Astronautics (a Finnish company that is also developing the WISA Woodsat wooden satellite).

Of course, wood also poses challenges for spacecraft engineers. As a natural material, wood can have imperfections and does not behave uniformly in different directions.

Research by Raphaela Günther, a PhD student at the Technical University of Dresden, is working to create spacecraft materials from wood fibers and bonding materials that behave more consistently.

“The question is not whether we start using more sustainable spacecraft materials,” Günther asserts. “I think we have to.”

With these promising advances, the dream of a “green” future in space is becoming closer to reality.

Source: https://dantri.com.vn/khoa-hoc/ve-tinh-go-song-sot-116-ngay-mo-ra-ky-nguyen-moi-cho-tau-vu-tru-20250713221702141.htm

Comment (0)