Beyond expectations

In the first 6 months of 2025, Dak Nong Aluminum Company - TKV (DNA) recorded impressive production and business results, creating a solid foundation for completing and exceeding the annual plan.

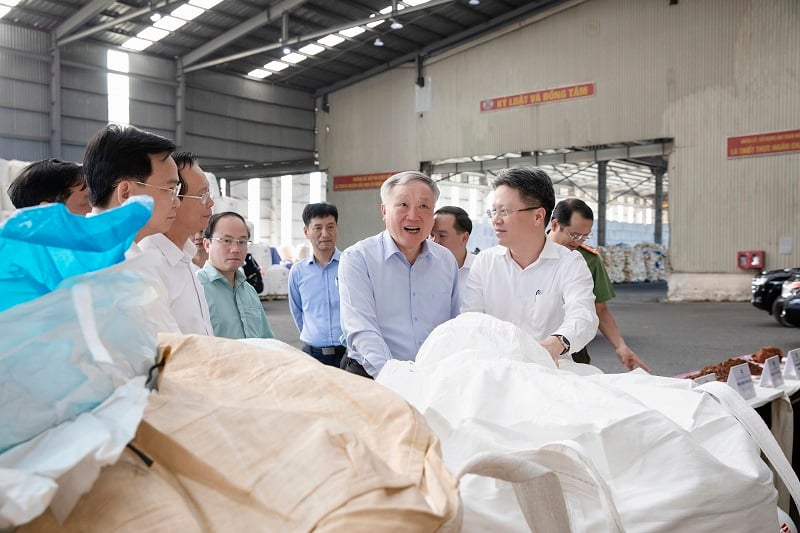

Permanent Deputy Prime Minister Nguyen Hoa Binh visited and inspected the production, business and investment situation at Dak Nong Aluminum Company.

Specifically, revenue reached over VND 1,920 billion, equal to 56.6% of the annual plan, up 7% over the same period in 2024. In particular, profit reached VND 84.5 billion, nearly 3 times higher than the target assigned by the Vietnam National Coal - Mineral Industries Group (TKV).

Converted alumina production output reached 364,563 tons, equal to 56.1% of the plan; consumption output reached 354,910 tons, equal to 103.8% over the same period last year. Average salary per employee reached 18 million VND/month, up 10% over the same period. The company paid 290 billion VND to the state budget, completing 84.4% of the yearly plan and increasing 182% over the same period in 2024.

In the context of many difficulties such as lack of mining area due to problems in site clearance, fluctuations in raw ore quality, etc., the company still maintains stable operation of the entire chain, ensuring efficiency, reducing costs and improving economic and technical efficiency. The main consumption indicators such as coal, lime, and electricity are all strictly controlled, in accordance with the group's production optimization standards.

Accelerate to conquer big goals

Entering the second half of 2025, Dak Nong Aluminum Company aims to complete an output of 720,000 tons of alumina, revenue of VND 3,752 billion and profit of VND 117.8 billion. These are strategic targets, which are decisive for the implementation of TKV's 5-year plan 2021-2025 in the alumina industry.

Dak Nong Aluminum Company's aluminum products are strictly tested for quality and exported to many major markets.

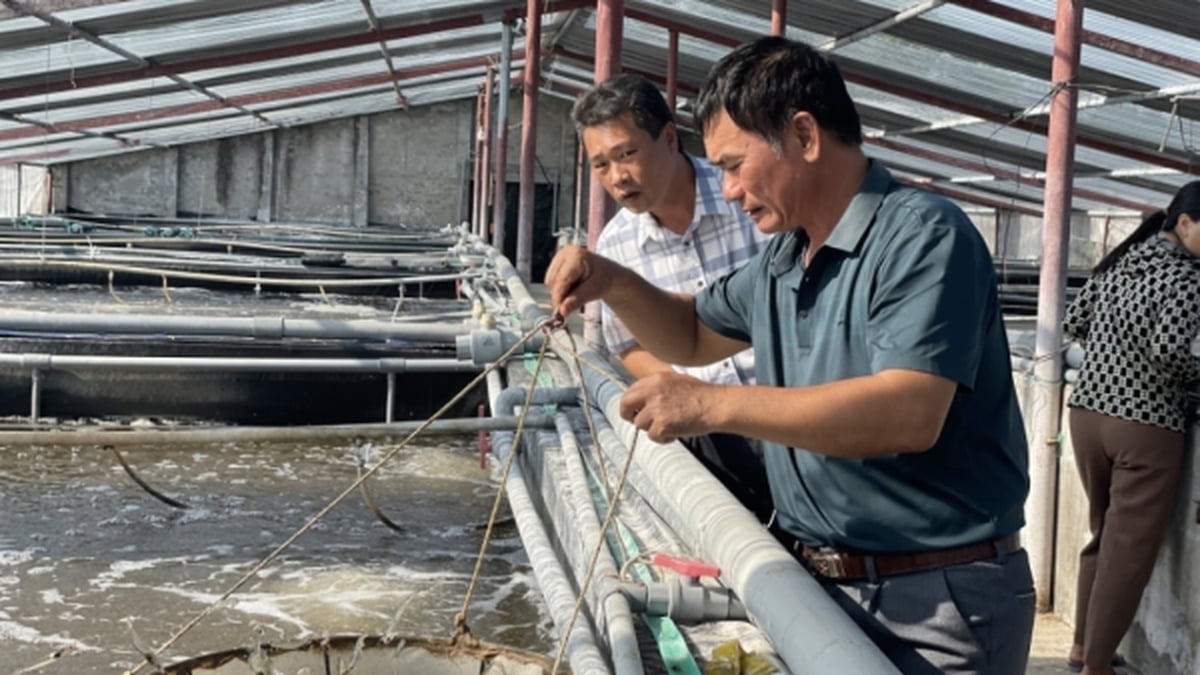

To realize this goal, the company continues to synchronously deploy groups of solutions: speed up compensation and site clearance to ensure sufficient mining area; increase ore blending and neutralization to improve ore quality; adjust processing technology to increase processing revenue and improve crystallization efficiency.

Along with that, DNA promotes the application of digital technology and automation throughout the entire production line. The smart production management system MES has initially shown its effectiveness, helping to control operational data in real time. The company is also building a comprehensive digital transformation model by 2030, including an internal ERP system, human resource management software, alumina consumption and barcode traceability.

Safety and environmental work is maintained at a high level. The company has completed 90% of the storm prevention plan; environmental monitoring indicators are regularly within the allowable limits. Key projects such as red mud lakes and tailings lakes all have standardized response plans and are periodically rehearsed.

Besides production, the company continues to carry out its social responsibilities in a practical way: it has spent more than 10 billion VND in the first 6 months of the year on activities such as building schools, supporting the elimination of temporary houses and granting scholarships to poor students in Dak R'lap district - where the business is located.

With a strategic vision, determination to innovate and drastic actions from the leadership system to the employees, Dak Nong Aluminum Company continues to affirm its role as a pillar of the mining industry in the Central Highlands. Conquering the output of 720,000 tons of aluminum in 2025 will not only be a milestone in production and business, but also a clear demonstration of the effectiveness of an advanced management model, sustainable development and high adaptability in the period of deep integration.

Source: https://doanhnghiepvn.vn/doanh-nhan/nhom-dak-nong-but-pha-loi-nhuan-tang-toc-chinh-phuc-720-000-tan-alumin/20250708090559662

Comment (0)