MIT has introduced a new robotic system that uses millimeter waves (mmWave) to detect defective products without opening the packaging. This technology allows robots to reconstruct 3D images of hidden objects, helping to determine the exact location, shape, and condition of products before they are put into use or shipped.

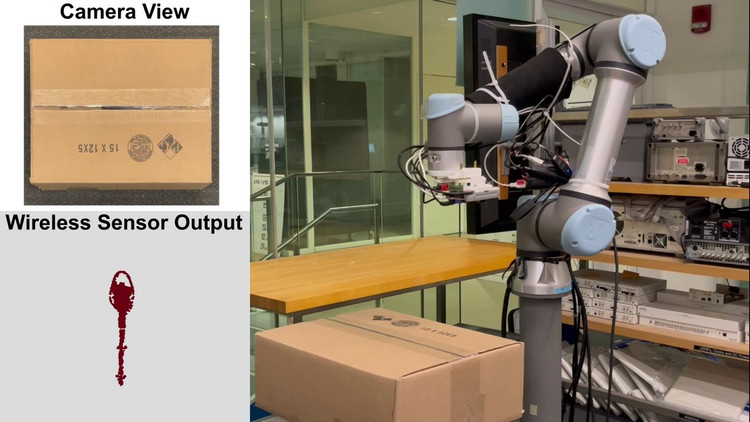

mmWave is a form of electromagnetic wave with a frequency of 30 to 300 GHz, commonly used in radar and 5G communications. Because mmWave signals can penetrate materials such as plastic, cardboard, or fabric, they can reflect off objects inside without direct contact. Based on that reflection data, the system can reconstruct a 3D image of the object in space.

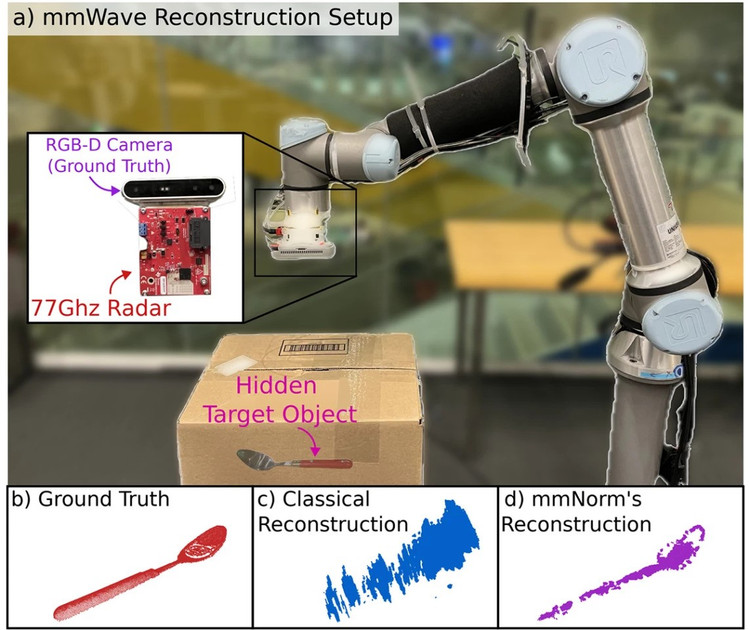

To improve accuracy, the MIT team developed a new algorithm called mmNorm. The system not only reconstructs the basic shape but also analyzes the surface curvature by collecting reflections from many different directions. Each point on the object has a direction of strongest reflection, which helps determine the tilt and overall shape accurately. Test results show that mmNorm produces 3D images with about 40% less error than previous technologies.

The system has been tested with more than 60 common objects such as cups, hand tools, and kitchen appliances. The mmWave radar is mounted on a robotic arm, performing non-invasive scans and collecting data in real time. The technology can work well with objects made of many materials, even in environments with many distracting factors.

Integrating this technology into a production line or warehouse would allow robots to automatically identify defective, dented, or incorrectly packaged products and remove them before delivery. In a manufacturing environment, robots could pick the right tool from a pile of mixed items without human assistance. The development team also proposes using the technology in augmented reality (AR) glasses, which could help visualize obscured objects in industrial spaces or technical installations.

However, mmWave technology still has certain limitations, especially when dealing with objects with low reflectivity or covered by thick layers of material. The research team is continuing to perfect the algorithm to increase 3D image resolution and improve reconstruction capabilities in more complex real-world conditions.

The combination of mmWave and autonomous robots is bringing new directions to the inspection and quality management industry. This technology contributes to improving operational efficiency, minimizing risks and expanding the application of robotic systems in modern manufacturing.

Source: https://khoahocdoisong.vn/robot-hoc-cach-nhin-xuyen-do-vat-nho-song-milimet-post1553263.html

Comment (0)