Positive signals for the development of ecological industrial parks

The Global Eco-Industrial Park Program (GEIPP) in Vietnam has been implemented since 2019, divided into two phases: Phase one (2019 - 2024) aims to demonstrate the effectiveness of the model and phase two (2024 - 2028) aims to replicate and promote the circular economy . According to Ms. Nguyen Tram Anh, GEIPP Vietnam National Project Manager, United Nations Industrial Development Organization (UNIDO), the goal of the program is to increase the efficiency of resource use, thereby improving the economic, social and environmental efficiency of enterprises in industrial parks.

Currently, there are six industrial parks in the North, Central and South regions participating in the program, selected from more than 20 industrial parks initially assessed. After 4 years of participation, industrial parks such as Deep C (Hai Phong), Amata (Dong Nai), Hiep Phuoc ( Ho Chi Minh City) ... have all recorded positive changes.

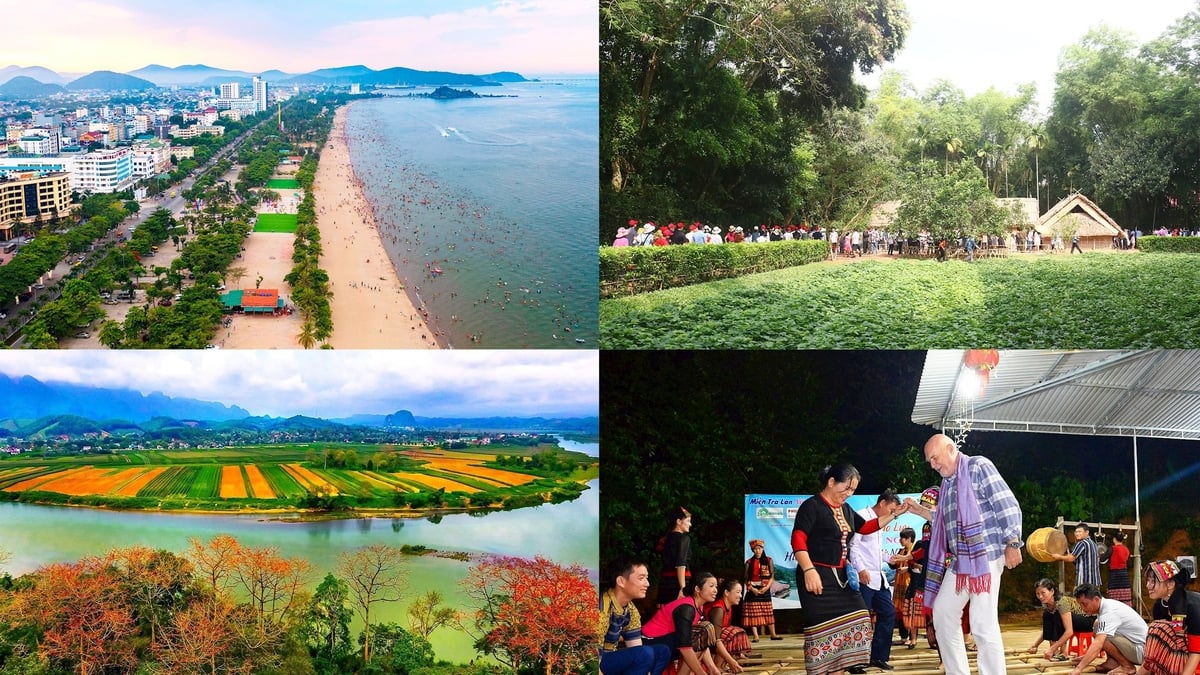

Nam Cau Kien Industrial Park meets many criteria in building an ecological industrial park. Illustrative photo

At Deep C Industrial Park , the rate of meeting the criteria according to the international framework for eco-industrial parks has increased from 47% in 2019 to 83% in 2024; Amata Industrial Park increased from 81% to 86%; Hiep Phuoc Industrial Park from 44% to 76%. “ Industrial parks must meet 100% of the criteria according to the international framework because there are indicators that are not practical for Vietnam's conditions. However, the goal is to aim for the highest possible level, ensuring real efficiency ,” Ms. Tram Anh emphasized.

A specific example, the steel factory in Da Nang , after applying cleaner production, saved 1,516 million VND/year, reduced 4,338 tons of CO2 per year and saved hundreds of megawatt hours of electricity. The rare earth magnet factory in Hai Phong also achieved savings of up to 1.6 billion VND/year. These are convincing evidences of economic and environmental efficiency when businesses apply solutions for industrial circulation, reuse and symbiosis.

Ms. Tram Anh also informed that according to the general report from UNIDO, the three industrial parks participating in the program have saved nearly 15,000 MWh of electricity/year, 264 terajoules of fossil fuels, reducing emissions of nearly 139,000 tons of CO2/year. In addition, more than 436 cleaner production opportunities have been implemented with a total investment of about 3.3 million USD. Most notably, the payback period is not long, with some businesses taking only about a year.

However, the special feature of the eco-industrial park model is the development of "industrial symbiosis", which means that businesses in the industrial park share resources. The waste of one business becomes the input of another. At the Amata industrial park, Pepsi and Green Energy Company have created a symbiotic model, creating a fairly effective model. In which, Green Energy Company burns rice husks, coconut shells, and waste wood to provide saturated steam for Pepsi, helping to recycle 60,000 tons of biomass waste and reduce 16,156 tons of CO2/year.

At Deep C Industrial Park, waste glass powder from the Flat Glass Group’s glass grinding process is used as a landfill material. At Khanh Phu Industrial Park (Ninh Binh), CO2 emissions from the Ninh Binh Nitrogen Plant are recovered and liquefied for use in food and medicine, helping to reduce emissions by up to 74,000 tons of CO2 per year.

Barriers to be removed

Despite the huge potential, the transition to an eco-industrial park model in Vietnam still faces many obstacles, according to Ms. Tram Anh. First of all, legal regulations are not really consistent, making it difficult for businesses to reuse waste or connect to industrial symbiosis. “ The process of applying for permission to reuse or industrial symbiosis is often very long and complicated, which can easily discourage businesses, ” Ms. Tram Anh shared.

Many current industrial parks do not meet the criteria for shared infrastructure under Decree 35. Current regulations require a minimum of 20% shared infrastructure, but most industrial parks currently do not meet this requirement. In addition, the lack of a platform for connecting and sharing information also reduces the ability to coordinate between businesses in an industrial park, while this is a core factor for industrial symbiosis.

Another very important issue is green finance . Although there is no shortage of capital from international organizations, the connection between businesses and lending and guarantee organizations is still very difficult. Accordingly, Ms. Tram Anh proposed that there should be more flexible and transparent mechanisms to promote businesses' access to green capital.

Based on the actual implementation of the project to build an ecological industrial park in Vietnam and the challenges mentioned above, in order to develop this model, Ms. Tram Anh made some recommendations: It is necessary to build a specific conversion roadmap for each industrial park, based on clear and realistic data of the enterprise.

State management agencies continue to improve legal policies, remove barriers in waste circulation, licensing reuse and industrial symbiosis.

Strengthen training, raise awareness and skills for industrial park managers and enterprises in applying the eco-industrial park model. Build an effective green financial mechanism, connect enterprises with investment capital sources and technical support.

In particular, Ms. Tram Anh emphasized the potential of new industrial parks in the planning: “Currently, there are nearly 100 industrial parks being planned. This is a golden opportunity to incorporate ecological industrial park thinking from the beginning, combining automation, industrial symbiosis and circular economy right in the design process.”

It can be seen that eco-industrial parks are an inevitable strategy for Vietnamese industry to enter the green era. If we can take advantage of opportunities, remove bottlenecks and have real support from international organizations and local authorities, Vietnam can completely become a model of sustainable industrial development in the region.

Early orientation right from the first step of industrial park planning helps reduce costs and facilitate the formation and development of ecological industrial parks.

Source: https://congthuong.vn/phat-trien-khu-cong-nghiep-sinh-thai-kho-o-dau-409666.html

Comment (0)