1. Main segments in the Swedish food processing industry

Processed meat

Processed meat is the largest segment of the Swedish food processing industry, accounting for around 20% of the market. Popular products include sausages, cold cuts, canned meat, and frozen meats. These are important products in both the domestic and export markets. Sweden's main export markets for processed meat products include Germany, Denmark, and Norway.

The rise of plant-based alternatives has created new competition in this segment. Consumers are increasingly interested in plant-based meat alternatives due to their health and environmental benefits. This is forcing companies in the processed meat industry to innovate to maintain market share.

Dairy products

The Swedish dairy industry is one of the strongest segments, with dairy products accounting for 17.3% of the total food processing industry. Dairy products such as fresh milk, cheese, butter, and yogurt are very popular. Large companies such as Arla Foods play an important role in supplying products to the domestic and export markets.

Lactose-free products and plant-based alternatives like oat milk and almond milk are also thriving, meeting consumer demand for healthy and sustainable products.

Candy and snacks

The Swedish confectionery and snack industry accounts for about 13.6% of the market. Confectionery products including chocolate, chewing gum, and biscuits are very popular in the domestic market. However, consumer trends are shifting towards products that are low in sugar and high in nutrition, as consumers become increasingly health conscious.

Plant-based foods

The rise of plant-based foods is one of the strongest trends in the Swedish food industry. Meat alternatives made from soy, peas, and other plant-based products are becoming more popular than ever. Companies like Oatly have helped make Sweden a pioneer in this field, with its oat milk products enjoying strong sales at home and abroad.

Beverages and processed foods

The beverage industry includes a wide range of products, from juices, coffees, to alcoholic beverages. Non-alcoholic and organic beverages are growing rapidly, especially organically certified juices and coffees. Additionally, processed products such as canned soups, fast foods, and frozen foods are gaining popularity due to the changing lifestyles that demand convenience.

Technology plays a key role in increasing productivity and improving product quality in the Swedish food processing industry. Advanced technologies such as artificial intelligence (AI) and the Internet of Things (IoT) are being used to monitor and optimize production processes, helping to reduce food waste and improve efficiency. This not only helps businesses increase production efficiency but also minimizes their environmental impact.

Food packaging technology has also made great strides. Swedish companies are adopting recyclable and environmentally friendly packaging to meet growing consumer demands for sustainability.

The food processing industry plays an important role in the Swedish economy , not only ensuring food supplies for the domestic market but also generating large export values. Processed meat, dairy and plant-based food products are exported to many European countries, especially the Nordic countries such as Denmark, Norway and Germany. In addition, this industry also creates tens of thousands of direct and indirect jobs, helping to maintain stable economic growth.

Sweden has also become a leading exporter of processed foods, particularly in the organic and sustainable food sector. Companies such as Arla Foods and Oatly have not only contributed to the country’s brand value but have also helped to position Sweden as a global leader in sustainable food.

2. OECD Outlook: Will the Global Economy Survive Trade Pressures in 2025?

The Organization for Economic Cooperation and Development (OECD) forecasts that global economic growth will continue to slow in 2025, mainly due to rising trade tensions, persistently high inflation and tightening financial conditions. Among them, uncertain tariff policies from the United States are identified as one of the factors with significant negative impacts.

Global GDP forecast to slow in 2025

According to the OECD, global gross domestic product (GDP) is expected to grow by just 2.9% in 2025, down from 3.3% in 2024 and lower than the previous forecast of 3.1%. This growth rate is expected to remain the same for 2026. Countries such as Italy, Norway, France, Mexico and Germany are expected to grow the slowest, while Costa Rica, Denmark, Ireland, Poland and Israel will lead the growth.

Russ Mould, investment director at AJ Bell, commented that while the downward revision was not large, “it is still enough to worry investors, particularly in the mining sector, where metals prices could come under pressure due to weaker demand.”

The situation is getting more tense as the 90-day moratorium on new US tariffs is about to end, forcing countries to speed up negotiations with the Trump administration. Sources said Mr. Trump wants to receive the “best offer” on trade by Wednesday to avoid a stalemate.

In 2025, the OECD forecasts global output will grow by 2.6%, with the US growing a modest 1.1%.

Inflation forecast 2025

Inflation in OECD member countries is estimated at 4.2% in 2025 – up from the 3.7% forecast in December. By 2026, it will fall to 3.2%, but still higher than initially forecast.

Türkiye is expected to have the highest inflation at 31.4%, followed by Colombia, Chile, Poland, Estonia and Hungary. Meanwhile, Switzerland, Finland, France, Sweden and Costa Rica will maintain lower-than-average inflation.

For the G20 group, average inflation is forecast at 3.6% in 2025 and easing slightly to 3.2% in 2026.

Recommendations from OECD

The OECD recommends that governments reduce trade barriers and pursue cooperative solutions rather than raising tariffs to support economic growth. Reforms related to supply chains, diversifying partners and common legal standards among countries are also considered effective solutions.

On monetary policy, the OECD advises central banks to maintain their priority on curbing inflation, while only easing interest rates in countries with a clear deflationary trend.

Finally, the OECD emphasizes the need to create a more stable environment for business investment by reducing policy uncertainty, promoting competition, removing barriers to market entry, and increasing access to finance for businesses.

3. Syre – H&M and Harald Mix’s polyester recycling company announces first three major customers, prepares to build first factory in Vietnam

Syre, a joint venture between fashion conglomerate H&M and the Vargas Investment Fund, founded by Swedish entrepreneur Harald Mix, has just announced its first three major partners in addition to its founding shareholders. Notably, two American retail giants: Gap and Target.

The first shipments are expected to begin in 2026, after some initial technical delays, according to Syre CEO Dennis Nobelius. Gap has committed to buying about 10,000 tons of recycled polyester per year, while Target will use Syre’s polyester for certain collections, though it has not disclosed how much. A third customer is Swedish outdoor brand Houdini, which has committed to buying half of its polyester needs from Syre over the next three years.

The three customers are not just buyers, but are also described as “launch partners” in materials development, reflecting Syre’s strategic partnership approach in the early stages of expansion.

Polyester – the world’s most common synthetic fibre, which is largely derived from petroleum – is currently only recycled on a limited scale, largely from PET bottles. Syre’s innovative recycling technology uses glycol – an environmentally friendly compound – to break down textile waste into monomers, which are then resynthesized into new polyester. The company says this process reduces CO₂ emissions by up to 85% compared to virgin polyester production.

Syre is completing a pilot plant and research center in North Carolina, USA, with a capacity of 10,000 tons/year, in cooperation with Portuguese company Selenis. The plant is expected to be operational by the end of 2026. From here, Syre aims to build 12 large industrial plants with a total capacity of 3 million tons of recycled polyester per year, starting with Vietnam in 2027.

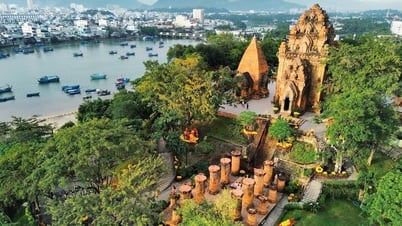

Vietnam - the first link in Syre's global expansion strategy

Vietnam was chosen as the location for Syre’s first industrial plant not only because of its pivotal role in the global apparel supply chain, but also because of H&M’s strong presence in the manufacturing ecosystem here. According to a report by H&M Group, Vietnam is among the top 5 sourcing countries, with more than 40 partner factories stretching from Hanoi to Ho Chi Minh City, focusing on textiles and apparel processing.

Initial information shows that the Syre factory in Vietnam will have a capacity equivalent to or higher than the facility in the US, built on a modular model, which can be easily expanded according to demand. Locating the factory in Vietnam not only serves the domestic demand for sustainable raw materials but also aims to export to major markets such as Europe and the US, meeting increasingly stringent requirements for transparency and emissions in the textile supply chain.

This is considered a strategic step by H&M and Vargas in restructuring the global supply chain towards circularity, while opening up new opportunities for Vietnam to participate more deeply in the global value chain in the field of material recycling technology.

In 2023, Syre successfully raised 1.1 billion kronor from reputable investors such as TPG Rise Climate (USA), Giant Ventures (UK), Norrsken (Sweden), Imas fund associated with IKEA, Volvo Cars, and Leitmotif (backed by Volkswagen). Although its partner in the Vargas Group, Northvolt, went bankrupt in March 2025, Syre affirmed that this event did not affect them due to differences in their fields of operation and implementation.

“We learned from Northvolt – that we need to respect scale, build step by step and not rush,” Mr. Nobelius emphasized, implying Syre’s careful and methodical approach to the first factory model in Vietnam.

Source: https://moit.gov.vn/tin-tuc/thi-truong-nuoc-ngoai/tong-hop-tinh-hinh-kinh-te-cong-nghiep-va-thuong-mai-thuy-dien2.html

![[Photo] Gia Lai provincial leaders offer flowers at Uncle Ho's Monument with the ethnic groups of the Central Highlands](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/7/9/196438801da24b3cb6158d0501984818)

Comment (0)