The Timely Man and the Miraculous Escape

In Zhongshan, a bustling industrial city in China’s Greater Bay Area, the mood seems to have eased. “Exports to the U.S. have returned to normal,” said Lai Jinsheng, general manager of EK Inc., a professional stage lighting company. A temporary 90-day tariff cut by Washington has created a “golden opportunity,” allowing containers of inventory that had been delayed for months to finally get on the road.

But Mr. Lai and others like him know that this is just a “brief calm in the storm.” The tariff “storm” has dealt a painful blow, not only reducing profits but also exposing the fragility of the single-market model. “Because American customers are the ones bearing the tariffs, their sales are affected, leading to a decrease in demand and thus our orders,” he analyzed.

But instead of sitting back and waiting in a “passive defense,” companies like EK Inc. have chosen a different path: “active evolution.” For them, the trade war is not the end of the road, but a costly wake-up call, a nudge that forces them to undergo a complete overhaul.

EK Inc. has been quick to diversify. The U.S. now accounts for only 30 percent of its export revenue, compared to Europe (40 percent) and other Asian markets (30 percent). Not only has it sought new customers, it has also built a factory in Malaysia, a strategic move to avoid tariffs and gain access to emerging markets.

More importantly, it has made a quantum leap up the value chain. Instead of remaining an obscure manufacturer, EK Inc. has decided to become a global force. In May, the company shocked the industry by announcing the acquisition of 100% of Claypaky, a legendary Italian stage lighting brand. The deal was not just a purchase, but a statement: a Chinese company now owns an icon of European technology and design, and holds both the heritage and the future of the industry.

EK Inc.’s story is not unique. Not far away, Quang Long Gas & Electrical Equipment Company is also writing its own survival story. Before 2018, 90% of its export orders were dependent on the US market, but now that number has dropped to 70% and the target is 50% in the next 3 years.

"Thanks to participating in previous international exhibitions, we have built a network of customers outside the US," said Mr. Luong Nhuy Co, Deputy General Director of the company. Orders from Korea and Japan, although smaller, bring good profit margins and, most importantly, stability.

These companies are the new face of “Made in China”: agile, diverse, and constantly evolving. They have turned the threat of the trade war into an opportunity to reposition themselves on the global map.

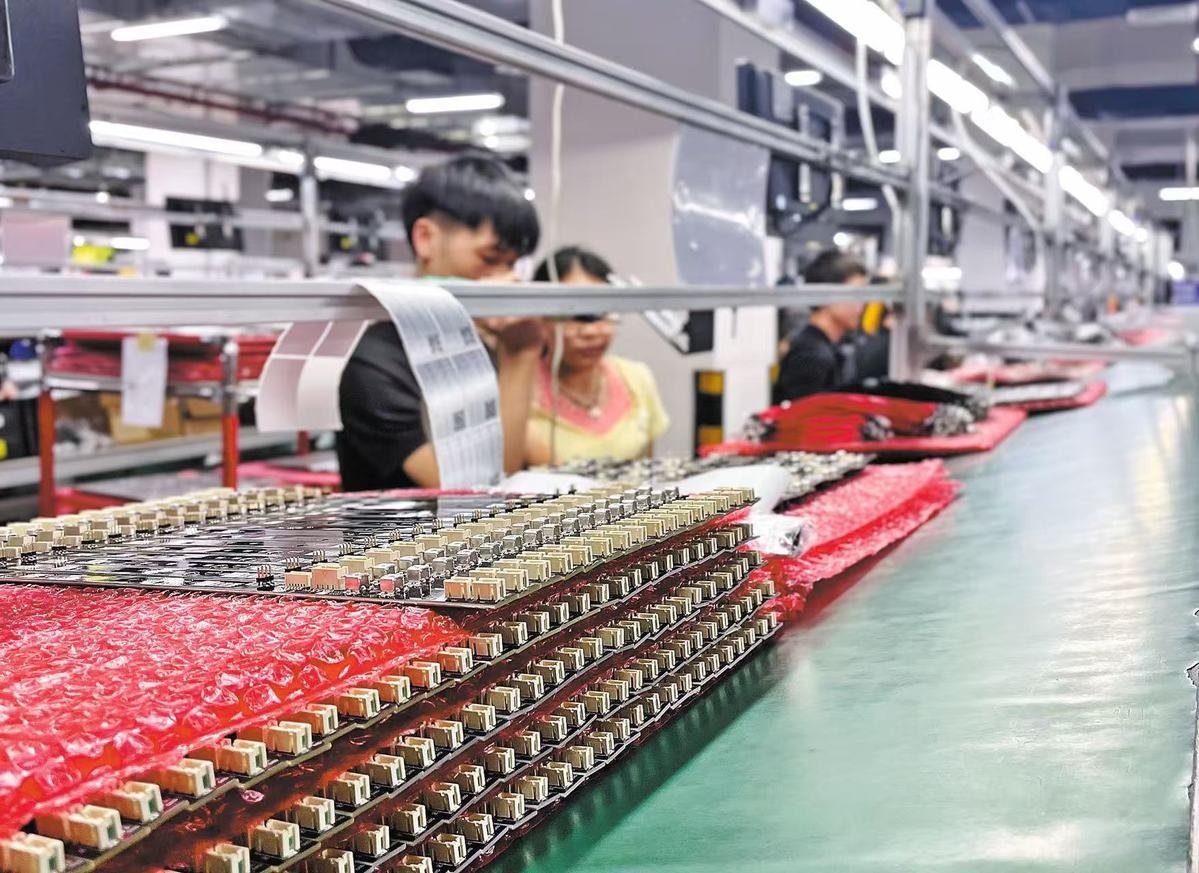

Workers assemble lighting products at EK Inc., a pioneer in the professional stage lighting industry, in Zhongshan City, Guangdong Province, China. (Photo: Qiu Quanlin/China Daily)

The trapped person and the "OEM trap"

But for every success story like EK Inc.’s, there are countless stories of frustration. Hundreds of miles away, Ms. Li, the owner of a longtime bicycle factory, is experiencing the downside of the trade war. Like tens of thousands of other businesses, she is stuck.

When Beijing urged exporters to turn to the domestic market to make up for their losses, Ms. Li saw a glimmer of hope. She rushed to apply for a 200 billion yuan ($27.41 billion) support program offered by e-commerce giant JD.com. But days passed and her application remained unanswered.

When she contacted them, she was told that the policy was only for sellers who already had stores. "The customer service staff had never even heard of any special support program," Ms. Ly bitterly recounted.

Her problem is not bureaucracy. It is exposing a deadly “trap” that has shaped much of China’s export economy for decades: the contract manufacturer (OEM) trap.

Ms. Li and others like her are invisible cogs in the global manufacturing machine. They produce high-quality bicycles, but they carry the brand of an American customer. “Selling them in China would violate intellectual property laws,” she explains. They have no brand, no distribution channels, no marketing expertise, and no right to sell their products in their home country.

Her lament contains the helplessness of a generation of entrepreneurs: "Every year we export hundreds of millions of yuan. Is that worthless?"

The answer, brutally, is that the value belongs to the brands they manufacture, not to them. They are masters of manufacturing, but novices in the game of branding and marketing. The government can offer huge support packages, but it cannot give them what they lack most: a brand and access to markets.

Disruption and the future of supply chains

The contrasting stories of Mr. Lai and Ms. Li are more than just two isolated fates. They represent a deep and irreversible divergence taking place within the Chinese economy. The trade war is merely a catalyst, accelerating a process that has been brewing for some time.

On one side are the “smart guys” like EK Inc., who have recognized the dangers of putting all their eggs in one basket. They have been quietly building up their R&D capabilities, looking for new markets, and most importantly, eager to build their own brands. For them, the tariffs are a shock, but also a last chance to finally “divorce” the low-cost manufacturing model. They are on their way to becoming true multinational corporations, competing on equal terms with their Western rivals.

On the other side are “trapped people” like Ms. Li. They were the backbone of the “ world’s factory” in the past, but now face an uncertain future. Caught between tariffs in export markets and intellectual property barriers in the domestic market, their options are increasingly limited.

Many Chinese manufacturers face domestic difficulties amid trade tensions and tariffs (Photo: SCMP).

This decoupling will reshape not only the Chinese economy but also global supply chains. The era of a monolithic, homogeneous “Made in China” is over forever. In its place is a more complex picture:

The rise of Chinese multinationals: Companies like EK Inc. will not only sell to the world, but also acquire brands, technologies and set up factories around the world, creating a new production and trade network.

Shift of low-end supply chains: Stuck manufacturers, if they want to survive, will have to look for customers in other markets or accept an increasingly fierce price war, which could lead to low-cost outsourcing orders continuing to shift to other countries such as India or Mexico.

The domestic market is a new battlefield: Conquering the Chinese domestic market is not an easy way out but a completely new battle, requiring branding and marketing skills that many exporters simply do not have.

The tariff war has exposed an undeniable truth: in a volatile global economy, manufacturing capacity alone is not enough. Adaptability, innovation, and brand power are what determine survival. In Zhongshan and countless other industrial centers, natural selection is in full swing, and the winners and losers of the new economic era are emerging.

Source: https://dantri.com.vn/kinh-doanh/thue-quan-va-cuoc-phan-hoa-ben-trong-cong-xuong-the-gioi-20250704155616341.htm

![[Photo] Politburo works with the Standing Committees of Vinh Long and Thai Nguyen Provincial Party Committees](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/9/8/4f046c454726499e830b662497ea1893)

![[Photo] General Secretary To Lam chaired the Politburo's working session with the Standing Committees of Party Committees of Central Party agencies.](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/9/9/8343386e1e8f43c6a3c0543da7744901)

![[Photo] Politburo works with the Standing Committees of Dong Thap and Quang Tri Provincial Party Committees](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/9/8/3e1c690a190746faa2d4651ac6ddd01a)

![[Photo] Politburo works with the Standing Committees of Phu Tho and Dong Nai Provincial Party Committees](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/9/8/f05d30279b1c495fb2d312cb16b518b0)

Comment (0)