Applying initiatives to improve work efficiency

Over the years, TMVI Production Limited Company ( Bac Giang Ward) has always been highly appreciated in the emulation movement "Good workers - Creative workers". One of the typical individuals is Mr. Do Van Ha (born in 1972), Head of the finished product delivery team at sewing group A8. Working at the company since its inception (2003), from a low-skilled sewing worker, thanks to constant training, he is now one of the highly skilled workers. Faced with increasingly strict requirements of export products, Mr. Ha has built a scientific working method, both reducing working time on the production line and increasing productivity and quality. Based on observations and analysis of technical factors of each stage, he also self-studied, researched, and gradually overcame and removed difficulties in the production process.

|

Mr. Do Van Ha - a typical individual of TMVI Production Limited Company with many technical innovation initiatives, exchanging sewing techniques with group members. |

Within 10 years (2015-2025), he had 3 initiatives that were highly appreciated by business leaders and applied in practice, contributing to cost savings and increasing labor productivity by 10-20%. Notably, the "Linked needle" initiative in 2022. Previously, 3 workers had to perform 3 different stages. When applying this initiative (joining two needles to a machine needle), the time to complete the product was halved, one less worker operated, accuracy was guaranteed, and the seams were also more beautiful. Mr. Ha shared: "I always keep in mind that I must complete the assigned tasks well. In each job, I need to be creative to increase labor productivity, both improving my personal income and helping the business develop." Thanks to that effort, from 2010 to now, every year Mr. Ha has been awarded "Excellent Labor" by the Board of Directors.

| According to the assessment of the Provincial Labor Federation, the emulation movement "Good workers - Creative workers" launched by trade unions at all levels has received positive responses from garment enterprises; the number of garment workers awarded for creative emulation accounts for 50-70% of the total number of outstanding individuals. |

On average, each year, workers at Thuan Thanh International Fashion Joint Stock Company (Xuan Lam Industrial Park, Song Lieu Ward) contribute dozens of ideas and technical innovation initiatives, contributing to increasing productivity and product quality. These proposals were quickly recognized and implemented by the company's management and trade union, bringing about clear results. A typical example is the initiative "Designing a production line layout suitable for workers' skills" by Ms. Nguyen Thi Hong Vui (born in 1982), a worker in sewing team H4. Previously, the sewing stages were intertwined, wasting a lot of time, and productivity was low (on average, 30 workers had to sew 330 jackets per day). From the end of 2024, Ms. Vui's initiative was applied, helping to completely overcome the above limitations. Sewing machines and workers are arranged in a U-shape to optimize communication and reduce redundant operations; establishing standard operations for each stage. Thanks to that, labor productivity increased by 20%; saving nearly 100 million VND/month for the business.

Technological innovation, increased competitiveness

The province currently has about 28,400 enterprises operating, creating jobs for more than 766,100 workers; of which, nearly 200 manufacturing enterprises are in the garment sector with about 100,000 workers, not to mention many small-scale establishments. According to the assessment of the Provincial Labor Federation, the emulation movement "Good workers - Creative workers" launched by trade unions at all levels has been actively responded to by garment enterprises; the number of garment workers awarded for creative emulation accounts for 50-70% of the total number of outstanding individuals. A typical example is Ha Phong Export Garment Joint Stock Company (Hiep Hoa commune), which currently has nearly 8,000 workers. Every year, the Executive Committee of the unit's Trade Union launches emulation, encourages workers to promote initiatives, improve techniques, and apply science and technology to increase productivity. Since 2020, the Company has issued a reward policy with specific regulations, the reward level ranges from 10 - 100 million VND/initiative. On average, each year, the company has 120-150 successful initiatives, bringing billions of VND in profit to the company.

|

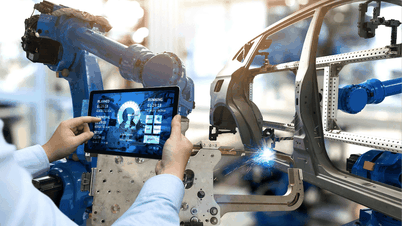

Production line at Crystal Martin Vietnam Co., Ltd., Quang Chau Industrial Park. |

In reality, in many industries and production fields, high labor costs are putting pressure on businesses. In the coming period, for the Vietnamese textile and garment industry, cheap labor will no longer be an advantage, while for a long time it has mainly been processing for brands with low profit value. Therefore, the development orientation of the textile and garment industry is to shift to a more efficient production method. Along with optimizing the human factor (training, encouraging creative competition, arranging appropriate human resources in each production stage), businesses need to further promote digital transformation, apply technology to production, and increase product competitiveness in the market.

As one of the long-standing enterprises in the textile and garment industry of the province, Bac Giang LGG Garment Corporation Joint Stock Company (Tien Luc commune) has implemented many solutions to improve labor productivity such as: Investing in automatic machinery, modern technology; applying advanced management software... This year, the company signed a strategic cooperation agreement with a business that owns Style 3D technology. This is considered an advanced solution, bringing breakthroughs in the design, production and sales process. With the ability to simulate vivid and accurate 3D images, Style 3D allows designers to create digital clothing models. Starting from sketching ideas to testing different materials and designs, scanning real object measurements and trying on products in 3D space. Mr. Luu Tien Chung, General Director of the Company said: “We work with customers on the Style 3D application, introduce them to fabric samples and immediately execute online design requests, change colors, fabric patterns, add or remove accessories on sample products. From the stage of selecting samples to the finished product according to customer requirements, it only takes a few days, while previously it took several months. This technology not only opens a marketing channel, reaching customers but also helps reduce time and production costs extremely effectively for businesses”.

Source: https://baobacninhtv.vn/thi-dua-sang-tao-chia-khoa-nang-nang-suat-nganh-may-postid425034.bbg

![[Photo] Multi-colored cultural space at the Exhibition "80 years of the journey of Independence - Freedom - Happiness"](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/8/26/fe69de34803e4ac1bf88ce49813d95d8)

![[Photo] Hanoi: Authorities work hard to overcome the effects of heavy rain](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/8/26/380f98ee36a34e62a9b7894b020112a8)

Comment (0)