Going down to the Weapon Repair Workshop, Weapon Repair Enterprise (Joint Enterprise Z751, General Department of Logistics and Engineering), we witnessed Major Truong Cong Su working hard with employees and workers to apply the topic "Research, design, and manufacture of thrust testing equipment for artillery system I".

This is the initiative of Major Truong Cong Su and his teammates who just won third prize in the Creative Youth Award in the Army.

|

Major Truong Cong Su tested his initiative in weapon repair. |

Major Truong Cong Su analyzed that according to technical standards, ground artillery during repair before general assembly must conduct testing of the oil and gas clusters (including reverse braking, pushing up, balancing, jacking the legs, and jacking the support platform).

These technical steps play an important role in determining the results of the practice step of firing the artillery and checking the technical specifications of the replacement materials produced in the repair. However, in the process of repairing artillery, artillery repair still lacks some equipment, including the "push-up tightness test" equipment. In addition, in the previous repair process, the Enterprise only had old equipment, which could only test the tightness at a maximum pressure of 130kg/ cm2 by using an industrial compressed air tank. This did not meet the technical requirements.

|

| Major Truong Cong Su guides workers in applying innovations to weapon repair. |

Overcoming these limitations and difficulties, Major Truong Cong Su and his teammates successfully researched the topic "Testing equipment for pushing up the gun system I". The product consists of: Cylindrical electrical and hydraulic system (1,500mm long; 900mm wide and 1,000mm high); 5.7KW motor, 260kg/ cm2 piston pump; 60 liter hydraulic oil tank volume; support frame and clamping parts...

The operating principle is based on the electro-hydraulic system, using an automatic high-pressure pump, pumping high-pressure hydraulic oil through a distribution valve and a specialized pipeline system. After testing, the technician only needs to change the direction of the distribution valve, the entire oil part pushed up will automatically return to the oil tank of the device and when the pressure for each type of firecracker is reached, the valve will be turned off and locked.

The manufacturing cost is only 250,000 VND/product. The initiative has helped the Weapon Repair Enterprise repair hundreds of artillery pieces of all types for military units in the Southern region, ensuring technical coefficients and safety of use.

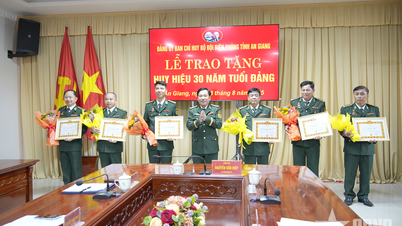

Talking to us, Colonel Bui Trung Kien, Director of the Weapon Repair Enterprise, said that before that, Major Truong Cong Su and his teammates also researched and successfully manufactured a "Set of measuring the firing pin protrusion of 60, 82, 100mm mortars in a fully assembled state", which can directly measure the firing pin protrusion of 60, 82, 100mm mortars when maintaining them in the barrel of the mortar, so that the measuring shaft head is pressed against the firing pin's support surface.

As a result, the unit has successfully produced maintenance kits and conducted technical inspections of various types of mortars at the Weapon Repair Enterprise. Through testing and test firing, it has been shown that the products operate reliably, with high accuracy, ensuring safety for people and technical equipment; practically improving labor productivity, meeting the set technical requirements.

Above are two of the 11 typical initiatives of Major Truong Cong Su from 2020 to present. The initiatives are all new, applying new science and technology, ensuring good repair and conversion of weapons during repair at the Weapon Repair Enterprise.

According to Major Truong Cong Su, repairing weapons that have been used for many years and degraded, and have no supplies or spare parts, it is difficult to repair weapons without initiative. "My initiatives are the result of hard work, timely detection of obstacles, difficulties or lack of supplies to research and develop creative ideas. When I have an idea, I proactively discuss with my teammates and listen to the instructions of my superiors to orient the creation of practical initiatives, immediately applying them to practical weapon repair," said Major Truong Cong Su.

Graduated from the Military Technical Academy in 2016, with the enthusiasm of youth, Major Truong Cong Su always actively learns and absorbs new knowledge, unit traditions, repair experience, creativity of senior officers and applies well the basic knowledge equipped at school into practice. Not only has valuable initiatives, Major Truong Cong Su is always exemplary in observing discipline, living simply, and being close to everyone.

In 2020, Major Truong Cong Su was awarded a certificate of merit by the Minister of National Defense for his outstanding achievements in 2019-2020; by the Director of the General Department of Politics of the Vietnam People's Army for his outstanding achievements in the Movement "Youth of the Army forging virtues, training talents, being proactive, creative, and determined to win" in the period 2017-2022; by the Director of the General Department of Engineering (now the General Department of Logistics - Engineering) for his outstanding achievements in 2024, and was awarded many titles of Emulation Fighter at the grassroots level and many certificates of merit and certificates of merit from all levels.

Article and photos: VU VAN KHOA

Source: https://www.qdnd.vn/quoc-phong-an-ninh/xay-dung-quan-doi/nhung-sang-kien-sua-chua-vu-khi-cua-thieu-ta-truong-cong-su-834767

![[Photo] Images of the State-level preliminary rehearsal of the military parade at Ba Dinh Square](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/8/27/807e4479c81f408ca16b916ba381b667)

![[Photo] National Assembly Chairman Tran Thanh Man holds talks with New Zealand Parliament Chairman](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/8/28/c90fcbe09a1d4a028b7623ae366b741d)

Comment (0)