The waste treatment plant of the Eastern Waste Treatment Joint Stock Company is located in Village 5, Hai Ninh Commune, with a capacity of processing 135-150 tons of waste per day. Currently, the plant is processing all household waste and common industrial solid waste in the area, operating based on 2 main technologies: Composting and incineration.

In the previous phase, waste was classified, the organic part was aerobically composted to create compost, the non-degradable waste was put into the incinerator. Along with that, the factory also deployed auxiliary solutions such as treating exhaust gas with an aeration tank system, treating wastewater with biological and chemical tanks, recycling ash and slag into block bricks, and waste plastic into recycled plastic granules.

However, despite the application of many technologies, the rate of landfill waste is still high, and the incineration process still poses a risk of air pollution due to emissions and dust. Faced with this reality, the company has proactively upgraded and improved the entire technological chain to increase processing efficiency, reduce pollution and move towards sustainable development.

To optimize the treatment process, the company has focused on applying new technologies that are highly appreciated in organic waste treatment, investing in large-capacity industrial waste incinerators and building waste plastic recycling plants. In particular, the company has used high-quality microorganisms such as Sagibio (a product of the Institute of Environmental Technology, under the Vietnam Academy of Science and Technology) in the process of treating organic waste.

The application of microorganisms to replace chemicals helps reduce toxicity, shorten treatment time, thoroughly treat odors and ensure worker safety. This technology is environmentally friendly and in line with the green trend in waste treatment.

In addition, the Eastern Waste Treatment Joint Stock Company also cooperated with the Institute of Environmental Technology to design and install a large-capacity industrial waste incinerator. This incinerator has been licensed, won a State-level award, and strictly complies with environmental standards, helping to improve the quality of treatment, as well as thoroughly resolve the problem of waste congestion.

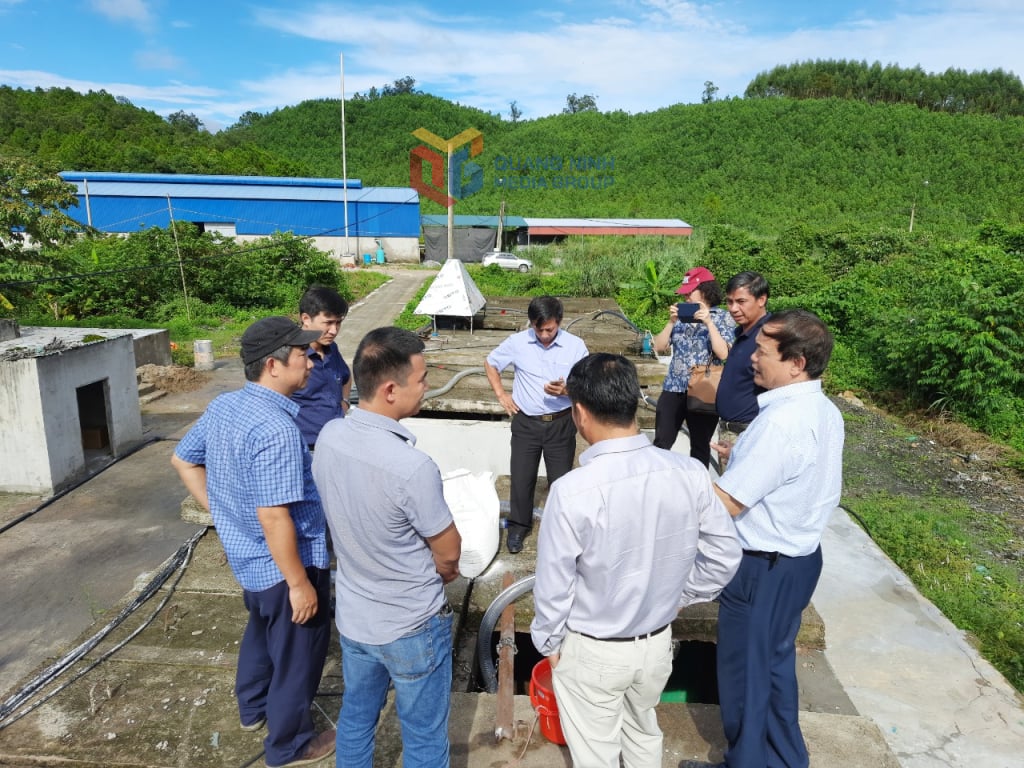

A highlight in the company's activities is the implementation of a state-level scientific project in collaboration with the Institute of Biotechnology and Food Technology (Hanoi University of Science and Technology). The project aims to build a system to treat leachate from landfills - a long-standing problem in localities.

Based on patent No. 7430 of the Intellectual Property Development Program for the period 2016-2020, a leachate treatment system was built at the factory with a capacity of 50m³/day and night. The equipment uses fluidized bed gas mixing technology and biological treatment to help introduce large amounts of oxygen into the wastewater, creating ideal conditions for microorganisms to operate effectively. As a result, the treatment time is shortened, while the quality of the water after treatment meets the standard of column B1 of QCVN 25:2009/BTNMT and other recommended indicators according to QCVN 40:2011/BTNMT.

Mr. Pham Tien Phong, Director of Eastern Waste Treatment Joint Stock Company, said: Resolution No. 57-NQ/TW dated December 22, 2024 of the Politburo has created a great driving force in the development of science and technology, innovation and digital transformation, helping Vietnam move faster towards a green economy and a circular economy. This resolution has helped guide the company's strategy in the coming time.

At the factory, components of household waste are exploited to create valuable products. Specifically, 80% of organic waste is processed into compost; about 40% of plastic waste is recycled into plastic pellets. Although there are still limitations such as unsorted waste at the source and difficult output for recycled products, the company is investing in additional sorting equipment and improving the process to increase the recovery rate, create higher value for products and minimize the amount of waste buried or burned.

In particular, the company is putting the waste plastic recycling factory into trial operation and initially recording positive results. Recycling plastic into reusable plastic granules helps reduce the negative impact of plastic waste - one of the current global environmental problems.

Source: https://baoquangninh.vn/ung-dung-cong-nghe-tien-tien-trong-xu-ly-rac-thai-nuoc-thai-3365122.html

![[OCOP REVIEW] Bay Quyen sticky rice cake: A hometown specialty that has reached new heights thanks to its brand reputation](https://vphoto.vietnam.vn/thumb/402x226/vietnam/resource/IMAGE/2025/7/3/1a7e35c028bf46199ee1ec6b3ba0069e)

Comment (0)