In the rapidly changing industrial ecosystem in Ho Chi Minh City, Dai Dung Group has emerged as a typical representative of Vietnamese enterprises capable of participating in projects requiring high technology and strict international standards.

|

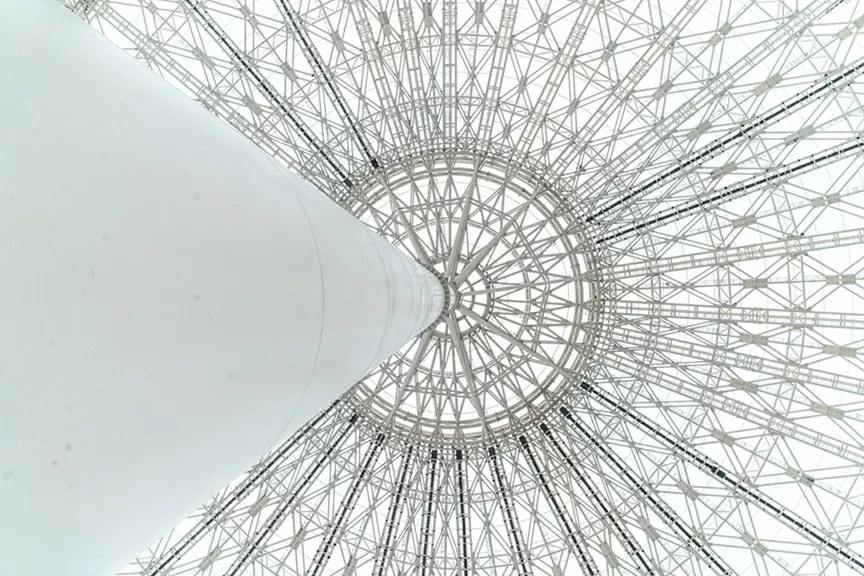

| Dome of the National Exhibition Center. |

That position is clearly demonstrated through a series of large-scale projects. The National Exhibition and Fair Center - one of the 10 largest centers in the world - owns a dome structure with a diameter of 360 meters, with a central pillar weighing hundreds of tons, a complex technical problem of space and load-bearing combination. The Hoa Phat Dung Quat Iron and Steel Complex with a warehouse spanning 170 meters - the largest span in Southeast Asia - demonstrates the ability to handle large structures with high precision. The Shiplift lifting floor system serving the US Navy has a load capacity of 25,000 tons, the main beam is 38 meters long, 3.5 meters high and weighs 110 tons, requiring quality control at the defense level. In the renewable energy sector, the Greater Changhua offshore wind power project (Taiwan) - with a capacity of 2.4 GW, with each base measuring 16 meters high, 14 meters in diameter, and weighing 350 tons - is a testament to the production and export capacity of a Vietnamese contractor on the global stage.

|

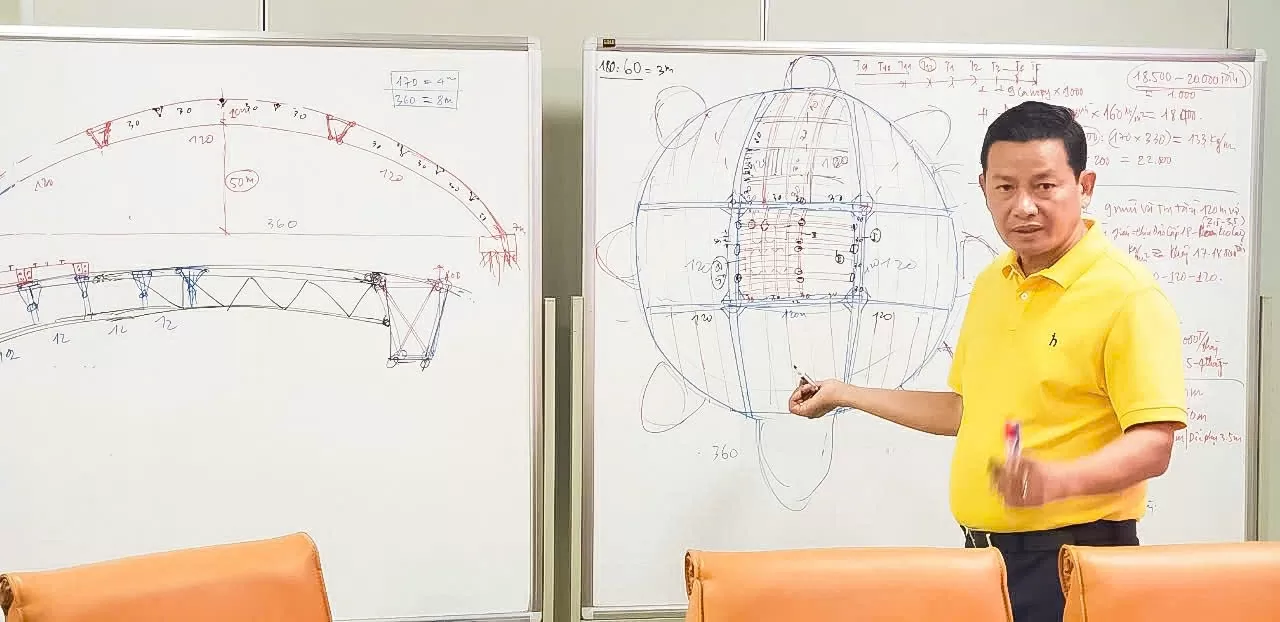

| 170m-span warehouse at Hoa Phat Dung Quat Steel Complex. |

Behind the complex series of technical works is the mark of Mr. Trinh Tien Dung - Chairman of the Board of Directors and General Director of Dai Dung Group, who is considered the "chief architect" in the group's integrated industrial development strategy. With a broad professional background, he directly oriented many outstanding design solutions from design, procurement, production, transportation and erection to help ensure the progress requirements of highly difficult projects - from super-heavy structures, large spans to full load testing complexes. The integrated thinking between engineering and operation helped him build a production - logistics model associated with seaports, creating a foundation for Dai Dung to participate in the global supply chain with projects requiring international standards and specialized construction organization capacity.

With his strategic vision, Dai Dung's factory system is planned in key economic zones in the South and Central regions, directly connected to deep-water ports and international airports such as Cai Mep - Thi Vai, SP-PSA, Gemadept, Cat Lai, Hiep Phuoc... Located on the main traffic axis, it helps shorten delivery time, optimize transportation and respond quickly to multinational projects - especially those requiring the transportation of large components along specific routes.

|

| Mr. Trinh Tien Dung, General Director and Chairman of the Board of Directors of Dai Dung Group. |

Not stopping at the production stage, Dai Dung is one of the few enterprises in the industry that owns the entire value chain - from providing solutions, designing, purchasing, manufacturing, transporting to implementing and installing at the construction site. Factories operate under the ISO 14001 environmental management system, products are certified with EPD and LEED Gold - certificates that demonstrate the commitment to reducing carbon emissions and meeting green criteria in construction. This is not only an ESG step, but also a core competitive advantage in the process of integrating into the global supply chain - where sustainability is becoming the norm rather than the exception.

|

| Offshore wind power base of Greater Changhua project. |

Along with infrastructure, the standards system is the pillar that guarantees the quality of every component manufactured. From ISO 9001, ISO 45001 to EN ISO 3834-2 and EN 1090-1 EXC4 - the highest level in the European standards system - allows businesses to meet the most stringent technical requirements. Certifications such as ASME (U, S, R Stamp), AISC (USA), CWB W47.1 (Canada), along with a series of emission measurement standards ISO 14067, ISO 14064 not only open up international markets but also affirm compliance capacity at the system level, which few businesses in the Southeast Asian region can simultaneously meet.

Super-heavy structures, in the end, are not only an achievement of the steel structure - mechanical engineering industry, but also the pinnacle of industrial organization. The ability of a Vietnamese enterprise to design, manufacture, assemble and export complex technical components to the global market is not simply a commercial success, but a concrete demonstration of the internal capacity of the industry. In that role, Dai Dung is contributing to positioning Vietnam as a core technical manufacturing center of the region - where structures are not only manufactured, but also refined as part of the national industrial identity.

Source: https://baoquocte.vn/ket-cau-sieu-truong-sieu-trong-tuyen-ngon-nang-luc-cong-nghiep-viet-nam-321911.html

![[Video] Warning about a series of clinics impersonating Bach Mai Hospital](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/7/23/e2e33e764470492584bcdf25e3feb09b)

![[Infographic] Vietnam-Senegal traditional friendship](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/7/23/4c96a604979345adb452af1d439d457b)

Comment (0)