As an inevitable trend, when Vietnam's major import partners are increasingly paying attention to ESG (environment, society, corporate governance) sustainable development indicators and using them as input standards to "test" goods and products that are Vietnam's export strengths, it has set requirements for manufacturers to have appropriate shifts.

Technology conversion, investment in upgrading equipment and digitalization of the entire operating process towards emission reduction, towards the Net Zero goal by 2030 as committed by the Prime Minister to the international community.

Representatives of industry associations and textile, garment and footwear enterprises shared about the practical implementation of green transformation and digital transformation models, lessons learned, and proposed support solutions for businesses to go further.

Mr. Vu Duc Giang, Chairman of Vietnam Textile and Apparel Association (VITAS):

To meet the strict requirements of major importers, Vietnamese textile and garment enterprises need to actively transform to adapt to changes in consumer trends and greening requirements of export markets. The application of technology, innovation and green standards not only help improve productivity but are also decisive factors for the industry to achieve sustainable development and increase competitiveness in the global market.

From now until 2030, the textile and garment industry will gradually shift its focus from rapid development to sustainable development, towards a circular economy . In the period from 2031-2035, the industry will effectively develop this model; at the same time, perfect the domestic value chain as well as participate deeply in the global supply chain. Improving productivity and product quality, combined with innovation and the application of green standards, will be the key to helping the Vietnamese textile and garment industry maintain its competitiveness and achieve sustainable development.

Mr. Than Duc Viet, General Director of Garment Corporation 10:

In the context of the textile industry being strongly affected by the "greening" trend and increasingly stringent requirements of international partners, Garment 10 Corporation has proactively built a sustainable development roadmap and strived to implement three main criteria in factory construction such as building a green production environment, using recycled or environmentally friendly materials and converting input energy sources. These criteria not only help the company meet the requirements of the international market but also affirm the company's commitment to sustainable development in the textile industry.

This “greening” trend is not only a mandatory requirement from importers but is certainly a great opportunity to help Vietnamese textile and garment enterprises increase the value of export orders.

Ms. Phan Thi Thanh Xuan, Vice President and General Secretary of the Vietnam Leather, Footwear and Handbag Association (Lefaso):

Green production is a common trend of leather and footwear enterprises today to maintain export turnover. However, the biggest challenge for the leather and footwear industry at this time is to meet the new standards set by many major footwear importing countries, which are sustainability in production, requirements for social responsibility...

While previously, sustainable development activities were mainly initiated and encouraged by customers, today they have been legalized through policies issued by the Governments of major footwear importing countries. Typically, the EU market has begun to introduce new requirements such as eco-design with sustainable designs, traceability and transparency of the supply chain. Changing policies of the import market will have a strong impact on businesses in the industry.

In the context of import markets requiring higher sustainability and transparency in production, businesses need to quickly improve and make transparent information about their product supply chains starting from raw materials, sustainable production towards a circular economy, ensuring responsibility to society and the environment.

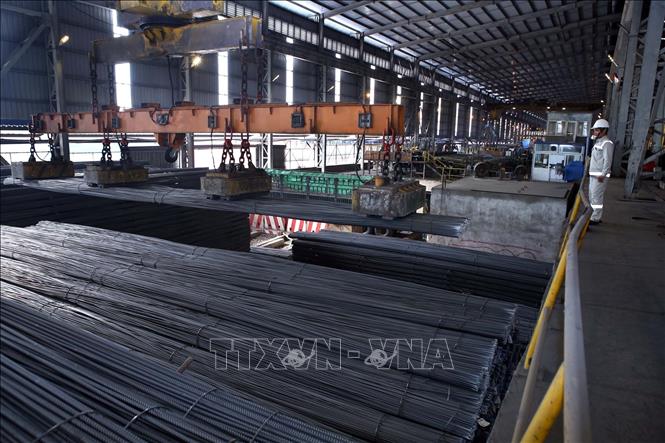

Mr. Nguyen Quang Loc, Head of Hoa Phat Dung Quat 2 Iron and Steel Complex Project:

Currently, many export markets require businesses to meet international standards, especially in reducing greenhouse gas emissions and producing “green steel”. This is something that businesses cannot do overnight but need a roadmap to transform production investment, requiring capital and time.

Recently, the Group has completed the greenhouse gas inventory, which is an important step in the Group's sustainable development strategy. Hoa Phat's policy is to proactively apply the latest quality, technology and operational standards to production and business. In the next roadmap, Hoa Phat will continue to optimize production to control greenhouse gases, meeting the requirements of new development stages.

In the coming time, to increase export orders, Hoa Phat will prioritize investment in developing high-tech steel and special steel for the mechanical engineering industry, automobile industry, shipbuilding, structural steel, etc. These are also the product development directions of the Dung Quat 2 project and future projects.

At the same time, Hoa Phat always focuses on optimizing all production stages in a circular, closed direction, reducing energy consumption and building a roadmap for developing green steel, reducing CO2 emissions according to the general direction of the Government, aiming for carbon neutrality by 2050...

Mr. Nguyen Duc Thuan, Chairman of the Board of Directors of TBS Group:

The opportunities and potential for the development of the Vietnamese leather, footwear and handbag industry are still very large. However, the "greening" trend in the world is increasingly demanding on businesses, especially export businesses. For businesses in the leather and footwear industry, the pressure to green transformation is very large when leather and footwear is an industry that still causes high levels of environmental pollution. Therefore, leather and footwear businesses cannot stay out of the Fourth Industrial Revolution, and need to apply automatic production lines, artificial intelligence (AI), green development... if they do not want to be eliminated from the global supply chain.

Lesson 3: Pressure on the value chain

According to VNA

Source: https://doanhnghiepvn.vn/kinh-te/xuat-khau-xanh-bai-2-lua-chon-song-con-de-tien-xa-hon/20250221103609837

Comment (0)