|

| Farmer Ho Sy Dai next to his family's Dai Phat Wood Pellet Production Facility (located in Bao Vinh ward). |

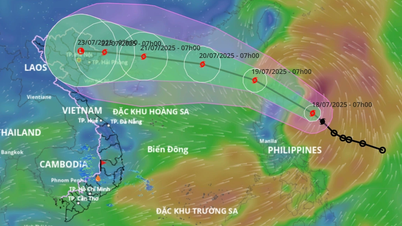

This is a clean product with completely natural ingredients and is used as a safe fuel, reducing environmental pollution, while contributing to solving the large amount of waste from cajuput bark. Mr. Dai's Dai Phat Wood Pellet Production Facility (located in Bao Vinh Ward) has been operating stably for about 2 years now and produces products in large quantities, meeting market demand.

Agile to adapt to the right model

One day in early July 2025, we visited Mr. Dai's Dai Phat Wood Pellet Production Facility, which covers an area of about 7,000 m2. The facility is operating stably and bringing in a decent income for the family, while also creating jobs for 12 local workers with an average salary of 15 million VND/person/month.

Talking about his entrepreneurial journey, Mr. Dai said that he was born and raised in a poor rural area of Nghe An province. He then followed his family to Dong Nai (his current residence) to live and settle down for many years. His family used to be involved in mushroom farming, but the consumption market was unstable, leading to low economic efficiency. From then on, he soon decided to change careers in the hope of a better future.

Through learning that cajuput bark waste in tree farms is often discarded in large quantities because people do not know how to exploit its value, Mr. Dai spent time learning and researching the values that cajuput bark brings. At the same time, he was introduced by relatives and friends to visit facilities that produce pellets from wood industry by-products to learn about the production process and create products.

| Sharing his plans for the future, farmer Ho Sy Dai said that he will continue to maintain a stable production scale of about 800-1,000 tons of pellets/month. In addition, he will promote the application of information technology by purchasing more modern equipment and machinery to serve the production process to improve product quality and design, meeting the increasing demands of the market and consumers. |

"After researching, I found that this profession is developing strongly and has many prospects, and the model is suitable for my family's conditions, so I decided to give it a try," Mr. Dai confided.

Thinking is doing, Mr. Dai decided to invest billions to purchase equipment and machinery (raw material grinders, product pellet compressors, etc.) and then put Dai Phat Wood Pellet Production Facility into official operation in 2023. "All beginnings are hard", Mr. Dai encountered many difficulties in the beginning because the model was completely new, while he did not have much knowledge and experience in this field. That caused the products to often not meet the requirements of size, design, and quality set by the market. However, it was these failures that helped him gain valuable experience to gradually perfect the products.

“In the production process to create the product, I encountered many difficulties in the stage of crushing the cajuput bark into raw materials before putting it into the compressor to create pellets. I spent a lot of time, effort and intelligence to adjust the grinder. The effort was rewarded, I finally perfected the raw material size to produce standard pellets, meeting market demand,” Mr. Dai confided.

Up to now, on average, each month, Mr. Dai's family has purchased about 2,000 tons of cajuput bark from tree owners in Dong Nai province and neighboring provinces to produce about 800-1,000 tons of pellets. Currently, his wood pellet production model is operating stably, the products are mainly exported to Japan, Korea... in large quantities. Thanks to that, his family's economy is increasingly prosperous and he has the conditions to take care of his children's education.

Create clean products for the market

When referring to the wood pellet production process, Mr. Dai shared his experience that the raw material (cajuput bark) after being purchased must be crushed twice by machine (the first time to create coarse powder and the second time to create finer powder). After that, the raw material is dried by machine or dried in the sun before being put into the pressing machine line to become the product.

According to Mr. Dai, he chose cajuput bark as raw material to produce pellets because this by-product is very popular in Dong Nai province and Binh Thuan province (old), the purchase and transportation of raw materials is very convenient, reducing production investment costs. At the same time, he wants to buy this type of scrap to increase the economic value of cajuput trees, while helping farmers have more income.

Mr. Le Viet Long, an official of the Farmers' Association of Bao Vinh Ward, commented that Mr. Ho Sy Dai is one of the typical farmer members, a good example of production and business in the locality. In the past, he did not hesitate to go to localities in the country to research and learn about the production process, creating pellets from cajuput bark and then successfully applying it to the local model. Mr. Dai is a pioneer in this new model and has brought about many positive results, helping the family economy to develop more and more and helping many local workers have stable jobs.

“The valuable thing is that Mr. Dai has created clean products to supply to the market, helping consumers use safe products. Therefore, in the past time, we have actively implemented many forms of promoting new models and clean products to create a spread in the community” - Mr. Long shared.

An Nhon - Minh Anh

Source: https://baodongnai.com.vn/kinh-te/202507/bien-rac-tram-thanh-tien-bien-rac-tram-thanh-tien-f77316d/

![[Video] More than 100 universities announce tuition fees for the 2025–2026 academic year](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/7/18/7eacdc721552429494cf919b3a65b42e)

![[Infographic] In 2025, 47 products will achieve national OCOP](https://vphoto.vietnam.vn/thumb/402x226/vietnam/resource/IMAGE/2025/7/16/5d672398b0744db3ab920e05db8e5b7d)

Comment (0)