Proactive risk prevention

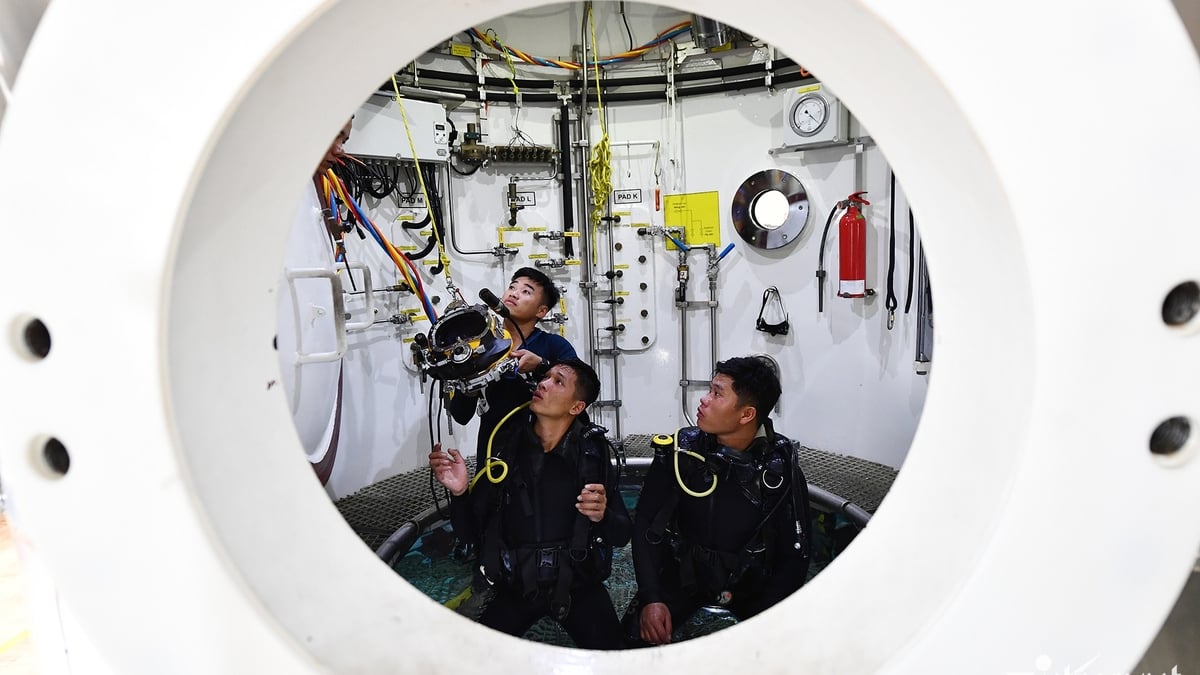

At Dak Nong Aluminum Company - TKV, occupational safety and health work has been implemented since the early days of its establishment and has been maintained systematically. The company has invested in adequate protective equipment for workers working in high-risk areas such as ore selection, alumina smelting, furnaces, etc. At the same time, it operates a regular environmental monitoring system to detect early hazardous factors such as dust, toxic gases, high temperatures. The company also organizes periodic occupational safety and health training courses for all officers and employees. The training content focuses on emergency response skills, first aid, fire prevention and fighting, and safe working procedures. Thanks to that, the rate of occupational accidents at the company has decreased significantly over the years, with no serious incidents occurring. Ms. Bui Thi Diem - Chairman of the Company's Trade Union said: "We continue to launch emulation campaigns to improve working conditions, at the same time, closely monitor the implementation of the regime for workers and compliance with occupational safety and health regulations."

Similarly, at An Phat Trading and Service Company Limited, Dong Gia Nghia Ward, occupational safety and health work is also placed on par with product quality. With the characteristics of an agricultural processing enterprise, including product lines that require clean and closed processing processes such as macadamia nuts, brown rice bars, dried nutritional seeds, ensuring a safe and hygienic working environment is a prerequisite. "From ventilation, lighting, anti-insect systems, to dust filters, the company has installed synchronously in production areas, helping the working space to always be clean, airy and limit the risk of occupational diseases", shared company director Tran Thi Diu.

Workers are regularly trained in short-term skills in using equipment and operating machinery safely. In particular, the company always has safety staff to coordinate periodic inspections of thermal equipment, packaging machines, dryers and storage areas. Thereby, early detection of risks that may affect workers. The company also organizes periodic health check-ups, closely monitors the health status of workers to have appropriate adjustment measures.

Core elements for sustainable development

In recent years, occupational safety and health work in Lam Dong province has had positive changes. Many enterprises have proactively integrated occupational safety and health activities into their annual production plans, built a network of occupational safety and health workers, coordinated periodic inspections and promptly handled violations. However, there are still many limitations in small enterprises and individual business households - where awareness of occupational safety and health is not high. Some places are not fully equipped with protective equipment, do not organize periodic training or are negligent in controlling risks in the workplace...

To overcome this, the provincial authorities are strengthening inspections and examinations on occupational safety and health. At the same time, they are stepping up propaganda and dissemination of laws, launching emulation movements such as: "Safe labor - effective production". In the coming time, Lam Dong will continue to focus on raising awareness, enhancing training, sharing experiences on occupational safety and health, as well as tightening supervision and strictly handling violations.

With the cooperation of the government and business community, Lam Dong hopes to build an increasingly safe, professional and humane working environment.

Source: https://baolamdong.vn/an-toan-lao-dong-uu-tien-hang-dau-tai-doanh-nghiep-386284.html

Comment (0)