Sharing about the journey of approaching UHMWPE, Mr. Nguyen Duy Phuong, Head of Technical Department of the Company, said: Previously, the unit mainly produced mechanical spare parts for the Coal industry. From 2022, the Company's Board of Directors decided to find a new direction from high-tech materials. UHMWPE is a prominent name.

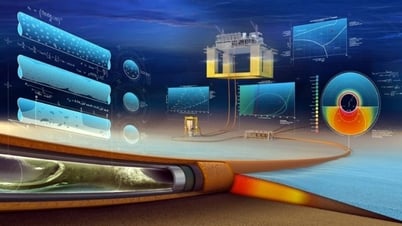

UHMWPE is a material with extremely high molecular weight (from 3-10 million Dalton units), usually only appearing in specific industrial applications, such as aerospace, military , medical. Hon Gai Mechanical has brought it into more practical applications, specifically the production of technical plastic pipes and plastic rollers with abrasion resistance, serving in the oil and gas industry, water supply and drainage, mineral exploitation, solid material transportation...

After a period of testing, including physical and chemical properties assessment, durability testing in salt, acid and impact environments, by mid-2024 the Company has established a semi-automatic production line for large diameter UHMWPE pipes and rollers, integrating many stages: Plastic granule processing, extrusion, cooling, shaping and quality testing with optical sensors. Many types of modern machinery and equipment have been invested to serve production, such as pipe cutting machines, 2-end pipe lathes, 2-end roller milling machines, ball presses...

According to Mr. Nguyen Thanh Long, Deputy Director of the Company: The weight of UHMWPE pipe is only 50% compared to steel pipe of the same size, but the abrasion resistance is many times higher (4-7 times higher than steel and rubber), suitable for transporting highly abrasive materials such as coal, sand, mud, cement. This helps to significantly reduce transportation and maintenance costs for customers, especially in mining projects or industrial sludge and wastewater systems. This success is not only the result of investment in modern machinery, but also comes from the spirit of innovation. The Company's team of young engineers has designed a number of mold parts suitable for material conditions, saving up to 40% of import costs from abroad.

The company currently produces about 2,000 tons of plastic pipes and 200,000 UHMWPE plastic rollers. The company's success is not outside the direction of digital transformation and green development of the province and the coal industry; that is, promoting the supporting industry to develop high technology, apply new materials, and create a sustainable value chain in the processing and manufacturing industry. Hon Gai Mechanical has caught the right rhythm and transformed from heavy mechanical production to smart mechanical production, high-quality products, serving many fields outside the coal industry.

These products achieve high stability in highly corrosive environments such as dilute acids or seawater. Also thanks to its non-toxic, fire-resistant properties, UHMWPE is being researched for application in fire protection, especially in underground fire-fighting water pipeline systems in coastal cities. Food processing enterprises, refrigeration industries, and other fields that require non-conductive, anti-static materials have expressed interest in this new material.

The successful production of UHMWPE plastic pipes and plastic rollers at Hon Gai Mechanical shows that domestic enterprises can completely enter the high-tech product segment if they have a methodical strategy. This is not just a commercial product, but a testament to the ability to learn, master and develop technology, gradually participating in the global production network. "We do not chase quantity. We aim for real added value, through sustainability, creativity and adaptability," affirmed Mr. Nguyen Thanh Long.

In the context of Vietnam strongly shifting to a green economic model, a circular economy and improving labor productivity based on science and technology, the story of technological innovation like that of Hon Gai Mechanical has widespread significance; affirming that innovation starts from businesses that dare to think, dare to do, and constantly seek ways to renew themselves for sustainable development.

Source: https://baoquangninh.vn/san-xuat-ong-con-lan-nhua-uhmwpe-3367815.html

Comment (0)