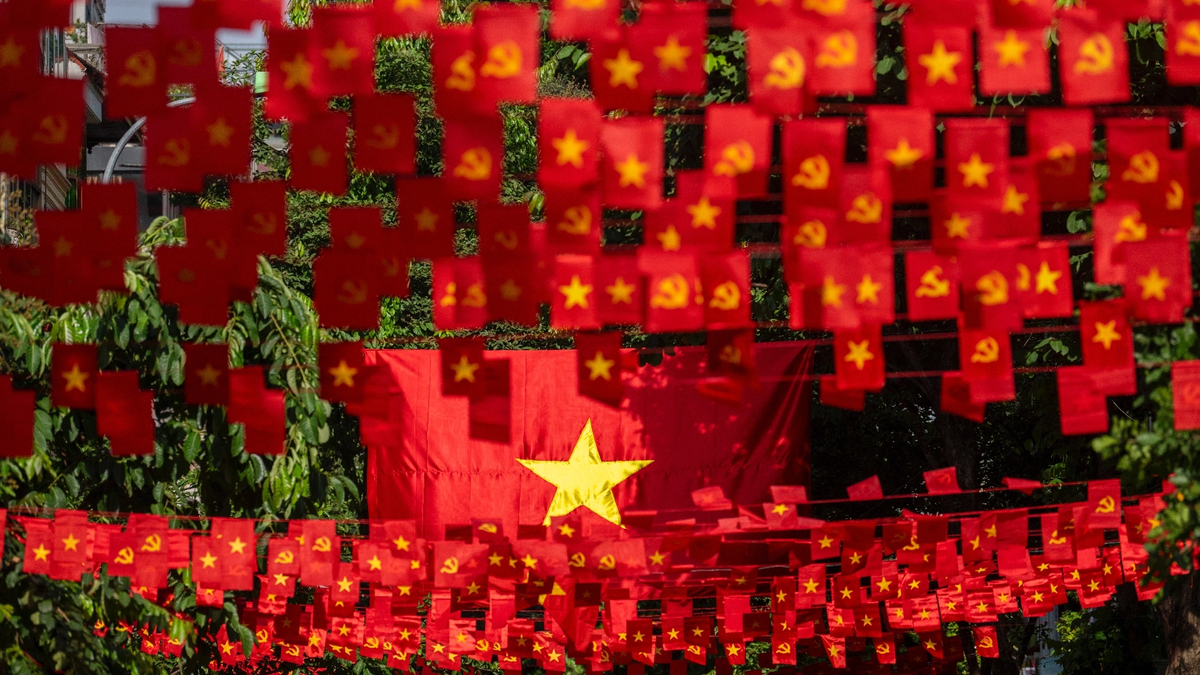

New technology - improving management and operation efficiency

After merging with the province, Bac Ninh Electricity Company supplies electricity to more than 1 million customers, including tens of thousands of administrative agencies, organizations and enterprises in industrial parks. This feature requires the unit not only to ensure safe and continuous electricity supply but also to improve service quality and reliability of electricity supply at the highest level. Comrade Do Quoc Long, Party Secretary and Director of the Company said: “Recognizing the political role and task of production development, the Party Committee of the Company identifies digital transformation as a breakthrough, an inevitable requirement to modernize the electricity industry, improve service efficiency for the people and businesses. From there, digital transformation work is included in resolutions and action plans of departments in the unit, with assignment, inspection, supervision and drastic and methodical implementation”.

|

Workers of Viet Yen Regional Power Management Team apply digital transformation in management and operation. |

On that basis, the Company has focused on investing and deploying many new technology application solutions, 44 automatic loops have been put into operation. This system helps connect and control remote switching devices, minimizing troubleshooting time and improving power supply reliability. The Company is also a pioneer in operating 110kV transformer stations in unmanned mode with 47/49 stations completely converted; the remaining stations operate in remote operation mode with supervisors, helping to optimize human resources and improve safety.

In particular, Bac Ninh Power Company has put into operation a number of digital transformer stations such as Que Vo 2 Transformer Station and Quang Chau 2 Transformer Station. These stations use digital control technology, allowing for monitoring, data collection and precise operation. In addition, connecting equipment to the SCADA remote control system is also focused on. To increase operational flexibility, the Company has implemented ring circuit and multi-split multi-connection projects with a total of 54 circuits. These rings play an important role in flexibly supplying power from multiple sources, shortening recovery time when local incidents occur, ensuring uninterrupted production and business, especially in industrial parks. The Company also promotes the application of equipment condition-based maintenance methods to promptly detect damage, thereby developing effective and cost-saving repair plans. To date, the Company has deployed this method to 2,015/2,494 devices on the medium voltage grid (reaching 80.79%) and 1,592/2,910 devices at 110kV transformer stations (reaching 54.71%). The application of drones to inspect the power grid has also been widely deployed, helping to inspect quickly, accurately, and ensure safety for workers.

In the field of electricity measurement and management, 100% of electricity meters have been replaced by electronic meters, of which 92.37% have remote measurement function. At 110kV transformer stations, the remote measurement rate reached 100%. The remote measurement system helps to automatically transmit meter readings to the server, serving the calculation of electricity bills, supporting the management of electricity losses, forecasting output and operating production effectively.

Convenient, customer satisfaction

Along with digital transformation in technology, customer service has also changed dramatically thanks to the application of digital technology . Level 4 online electricity services have been widely deployed on the National Public Service Portal and the Customer Care Center website. In the first 7 months of 2025, the Company received and resolved 44,580 electricity service requests, of which 16,890 requests were registered online via the National Public Service Portal. The resolution of 100% of requests at levels 3 and 4 shows a clear change in service quality, bringing convenience and satisfaction to customers.

Cashless payment activities also achieved positive results with 927,835 customers paying electricity bills without cash, accounting for 99.25%. The Company has integrated a variety of payment methods such as automatic debit via banks, payment via Internet Banking, public service portal, via Viettel, post offices, etc., and expanded collection channels to remote areas. A notable highlight is that digital transformation initiatives proposed by officers and employees in the Company have been recognized by the Northern Power Corporation. Typical examples include: Work order control solutions to increase transparency and labor safety; technical file management website to look up technical data at units; automatic abnormal monitoring system from EVNHES remote measurement data to promptly detect and quickly handle abnormalities on the power grid.

All production and business management work has also been digitized through D-Office electronic office software with integrated digital signatures. 100% of incoming and outgoing documents (except confidential documents) are circulated electronically, contributing to reducing paperwork, increasing processing speed, saving time and operating costs. Online meetings with Vietnam Electricity Group and Northern Power Corporation or within the Company are also held regularly to replace traditional meeting forms, ensuring flexibility and savings.

It can be affirmed that the comprehensive digital transformation at Bac Ninh Electricity Company has brought about practical results. The proactiveness, creativity and determination in the direction of the Company's Party Committee are the prerequisites for success. Digital transformation has contributed to improving operational efficiency, increasing labor productivity, improving service quality, and gradually modernizing the power system towards a smart grid, ensuring safety - stability - sustainability.

Source: https://baobacninhtv.vn/chuyen-doi-so-nen-tang-de-dien-luc-bac-ninh-phat-trien-ben-vung-postid424749.bbg

![[Photo] Prime Minister Pham Minh Chinh chairs the meeting of the Government Party Committee Standing Committee](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/8/23/8e94aa3d26424d1ab1528c3e4bbacc45)

![[Photo] General Secretary To Lam attends the 80th Anniversary of the Cultural Sector's Traditional Day](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/8/23/7a88e6b58502490aa153adf8f0eec2b2)

Comment (0)