From complex management problems to strict production standards of multinational corporations, the solutions developed by ITG Technology are proving their competitiveness beyond the region, chosen by a series of FDI enterprises and export factories as a strategic operating platform.

|

| 3S iFACTORY smart factory solution was honored with i4.0 Awards. Source: itgtechnology.vn |

Vietnamese solutions in the journey to conquer global factories

Born in the context of the explosion of the 4.0 industrial revolution, 3S iFACTORY developed by ITG Technology has quickly made its mark thanks to its high specialization in each industry and the ability to customize according to the characteristics of the business, helping to solve the "information gap" which is the root problem that many businesses encounter, especially foreign businesses when localizing the management system in Vietnam.

This is also the reason why many large FDI enterprises choose 3S iFACTORY instead of foreign solutions. Among them are factories of Canon Electronics, Panasonic Appliances, Hitachi Astemo, Varroc, Goshi - Thang Long, VPIC1, Niigata Vietnam... which are applying the solution to monitor real-time production, manage progress, quality, OEE, or traceability, which are strict requirements from the global parent corporation.

One of the clear examples is Tsukuba Die-casting Vietnam (TDV) - a member of the Japanese Tsukuba Group. With the expectation of building a world-class production system, TDV has chosen 3S iFACTORY as the core solution. The system helps synchronize the connection between office management and production areas, automatically collect data, analyze performance, warn of abnormalities and support full traceability. Thereby, the factory not only meets the quality requirements of international partners but also improves internal management capacity in a sustainable manner.

Not only foreign-invested factories, many Vietnamese export-oriented enterprises are also choosing 3S iFACTORY as a “digital operating ecosystem” to prepare for integration. A typical example is COSMOS – a component supplier for Honda, Toyota, Kyocera, which is applying the system to solve three key problems: production planning, warehouse operations management, and production progress management.

Or like HHP Global - a packaging company listed on the stock exchange, has applied 3S iFACTORY to control costs, plan flexible production and measure energy consumption according to ESG standards, serving large export orders.

Key to success: Technology autonomy - Management knowledge

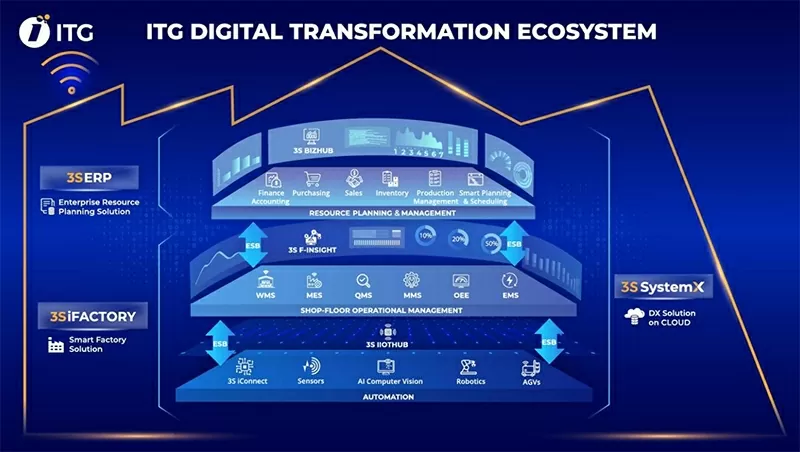

Behind the success of 3S iFACTORY is the Make-in-Vietnam product strategy but with international standard thinking and technology structure. The ecosystem includes modules: Smart production planning and scheduling axis (3S SPS), Smart warehouse (3S WMS), Manufacturing execution and execution (MES), Quality management (QMS), Maintenance management (MMS), Overall efficiency management (OEE), Energy management (EMS), Production site visualization (Factory Insight), Connectivity and automation (IIoTHUB).

|

| 3S iFACTORY solution is part of the comprehensive digital transformation ecosystem ITG Ecosystem. Source: itgtechnology.vn |

All are tightly connected through a unified system architecture, allowing modules to interact in real time and inherit data throughout the office and production site. This architecture helps ensure integrity, high accuracy and quick response to changes from operations. Thanks to the ability to flexibly integrate with the existing equipment, machinery and software systems at the factory, 3S iFACTORY can be effectively deployed for both large-scale FDI factories and domestic manufacturing enterprises looking for an industry-standard digital platform that is easy to expand and optimize for each stage of development.

With outstanding contributions to the journey of digitalizing production in Vietnam, 3S iFACTORY was recently honored at the Vietnam Industry 4.0 Top 2025 ceremony in the category of "Top enterprises with outstanding digital products and technology solutions in Industry 4.0". The event was co-sponsored by the Vietnam Union of Science and Technology Associations (VUSTA) in collaboration with the Vietnam Automation Association (VAA), the Institute of Innovation and Digital Transformation (VIDT) and ministries and sectors such as the Ministry of Industry and Trade , the Ministry of Science and Technology, and the Ministry of Information and Communications, to honor enterprises with outstanding products, solutions and services in the field of Industry 4.0.

This is not only a recognition from experts but also an important step of confidence, contributing to enhancing the position of Vietnamese technology in the global 4.0 industrial ecosystem.

Mr. Nguyen Xuan Hach - CEO of ITG Technology - shared: " The success of 3S iFACTORY is thanks to the technological autonomy and management knowledge that we have distilled through each digital transformation project. This is the foundation that helps the solution not only be highly customizable, but also meet the strict operating standards of international enterprises."

Recently, ITG also entered into a strategic partnership with Intel to integrate artificial intelligence (AI) into the 3S iFACTORY ecosystem. AI helps expand the capacity for analysis, optimization, and data-based decision making: from productivity forecasting, quality inspection, equipment performance analysis, to smart production scheduling. This is an important foundation for factories to not only digitize but also move closer to automation and smart operations.

With more than 1,200 factories under development from Vietnamese enterprises to foreign direct investment (FDI), ITG has been proving that Vietnamese technological capacity is capable of accompanying global enterprises. Not just a digital product, 3S iFACTORY is the crystallization of industry experience, deep understanding of the characteristics and determination to bring Vietnamese intelligence to the international market.

Source: https://baoquocte.vn/3s-ifactory-tri-tue-viet-chinh-phuc-doanh-nghiep-san-xuat-toan-cau-319082.html

![[Photo] Cuban artists bring "party" of classic excerpts from world ballet to Vietnam](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/6/26/797945d5d20b4693bc3f245e69b6142c)

![[Photo] General Secretary To Lam receives Australian Ambassador to Vietnam Gillian Bird](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/6/26/ce86495a92b4465181604bfb79f257de)

Comment (0)